EXCELLENCE

IN BOOTH

BEST IN CATAGORY

COMPETITION

BEST IN

WALLCOVERINGS

CATAGORY

The render of this photo was difficult. When I took this photo, many of the design sections were not in place. I wanted this shot for the contests and so I had to erase the inbetween sections of the bars and then layer a duplicated behind, while also layering other photos of the other booth of all the sections behind the bars to paste back into place. The signage and ombre floor was not completed until the final week of the exhibits and so I had to create and position them in perspective.

From the owner's simple few bar sketch, I designed what became the most popular feature of the WestEdge Lucille Studio Booth: The Aztec Honeycomb Screenwall. The idea came from our corner booth location: we didn't want to block the view of our booth in our high traffic area and so the see-through partition was developed.

The render of this photo was difficult. When I took this photo, many of the design sections were not in place. I wanted this shot for the contests and so I had to erase the inbetween sections of the bars and then layer a duplicated behind, while also layering other photos of the other booth of all the sections behind the bars to paste back into place. The signage and ombre floor was not completed until the final week of the exhibits and so I had to create and position them in perspective.

- WESTEDGE 2024 (LA, CA) -

LUCILLE STUDIO EXHIBIT BOOTH

Developing, CO-Designing, & Launching an entire product line.... while organizing the creation of a new company........ simultaneously designing two booths............ to debut at two different exhibitions... 3000 miles from each other.. and only 4 days apart. - in 6 months-

Let's just say I'm ready for just about anything now.

LAYOUT - WestEdge BOOTH - FRONT

-

DESIGN

-

ESTIMATION OF MATERIALS/TILES PER SECTION

-

DESIGNED PHOTOSHOP RENDER

DESIGNED / Engineered

-

ITEMS: Placement, Function, Construction

-

COLLASPABLE CONFIGURATION

-

4 Panel Wall Support System

-

Each Design Section:

-

Removable and Framed--Z-Clip Attachment to Support Panels

-

Overlapping design to add strength.

-

-

-

|  |  |  |

|---|

CLICK ON THE IMAGES

to read more about the directing process.

LIGHT IT UP!

The owner had wanted Neon Signs, but due to budget I developed signage with LED strip lighting behind wood with the letters cut out. This developed into Lasered acrylic signs lit with the LED strip lighting.

SIDE WALL LAYOUT - WestEdge BOOTH

"TAMBOUR WALL"

|  |  |  |

|---|---|---|---|

|

CLICK ON THE IMAGES

to read more about the directing process.

DESIGN -

- Items: Placement, Function, Construction, Shop Labeling of Sections and Booth Support Paneling

-

COLLAPSABLE CONFIGURATION

-

ESTIMATED- Materials needed for each section based on already processed order.

-

ESTIMATED- Materials needed for each section based on an already processed order by the owner.

-

The tambor came by the stick in linear board foot as is was custom designed and custom routed.

-

Much math...much, much math was needed to figure this wall's layout

-

The nine designs were ordered before this wall was designed.

-

Different amounts were ordered for different designs and the dimensions of each tambour repeat are unique to that design.

-

-

SHOP MANAGEMENT DIRECTION of Tambour Section assembly & Booth Labeling

LEFT SIDE WALL LAYOUT - WestEdge BOOTH

"AZTEC & HONEYCOMB SCREEN WALL"

CLICK ON THE IMAGES

to read more about the directing process.

|  |  |  |

|---|---|---|---|

|

Booth construction was located in the back corner of the Fabrication Shop.

In order to take this photo, I had to open a door to the Shop and take the photo while propping the door open with my foot. Fun times. I then had to squat down to take a second photo from underneath the Shop shelf that obstructed the view to the booth. Once I had both photos I juxtapositioned them together into the show stopper render of the WestEdge Booth showcasing the Screen Wall Exterior.

I'm very proud of this Image.

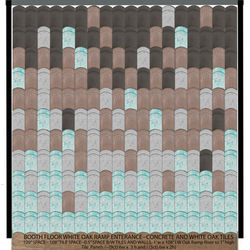

FLOOR LAYOUT - WestEdge BOOTH

CLICK ON THE IMAGES

to read more about the directing process.

|  |  |

|---|

All Videos

BOOTH & CRATE ENGINEERING

CONSTRUCTION PROCESS

BOOTH

DESIGN / Engineering

-

COLLASPABLE CONFIGURATION

- BACK WALL

- 4 Panel Back Wall System assembled with toggle table connectors

- Removable Design Panels

-

ANGLE BANGLE & WAVE Design Sections velcroed to remove for shipping

-

-

SIDE WALLS

-

3 Panel Back Wall System

-

Screen Wall assembled with screws for stability.

-

Tambour Panels assembled wit toggle table connectors

-

-

Corner Stability Ceiling Topper

-

I designed the slide on channeling system to fit the Back Wall and Side wall tops for installation ease.

-

-

- BACK WALL

-

OMBRE CONCRETE AND WOOD FLOORING

-

Designed and directed the sublayer for ADA Certification

-

interconnecting plywood floor paneling 30" x 36"

-

nonskid foam

-

-

CRATES

SHIPPING AND STORAGE

DESIGN / Engineering

-

SHOP MANAGEMENT LABELING AND INSTALL DIRECTION

-

LABELING-- I developed acronym codes for the Wall Support Panels, the removable design panel inserts, and for placement in the shipping crate.

-

Color Coded

-

Location Specific

-

-

Directed-- A Storage System and Instruction Handout for unloading the paneling of the booth from the crate in the order that it would need to be set up and also the reverse for break down and storage.

-

God Bless you Wes and Cathy!

-

-

-

-

CRATE DESIGN "EVERYTHING HAS IT'S PLACE" CONFIGURATION

-

Collaborated the crate construction to fit 108" panels inside a 92" x 93" x 102" shipping crate maximum. Diagonal from corner to corner on the side axis. Everything else fit around.

-

4 Panel Back System with table connectors

-